Do you have irregular tire wear? If so, you may be thinking it’s a wheel alignment, tire inflation, or axle issue because that’s what we’ve all been led to believe. Well, it’s time to let in some new information: irregular tire wear is often caused by improper bearing adjustments and the experts have known about it for years.

Missing Facts

In a recent Fleet Maintenance article, “Tire Forensics”, the author wrote an article to remind us that the wear patterns of discarded tires can provide a wealth of knowledge about maintenance practices. But, a few key facts were left out.

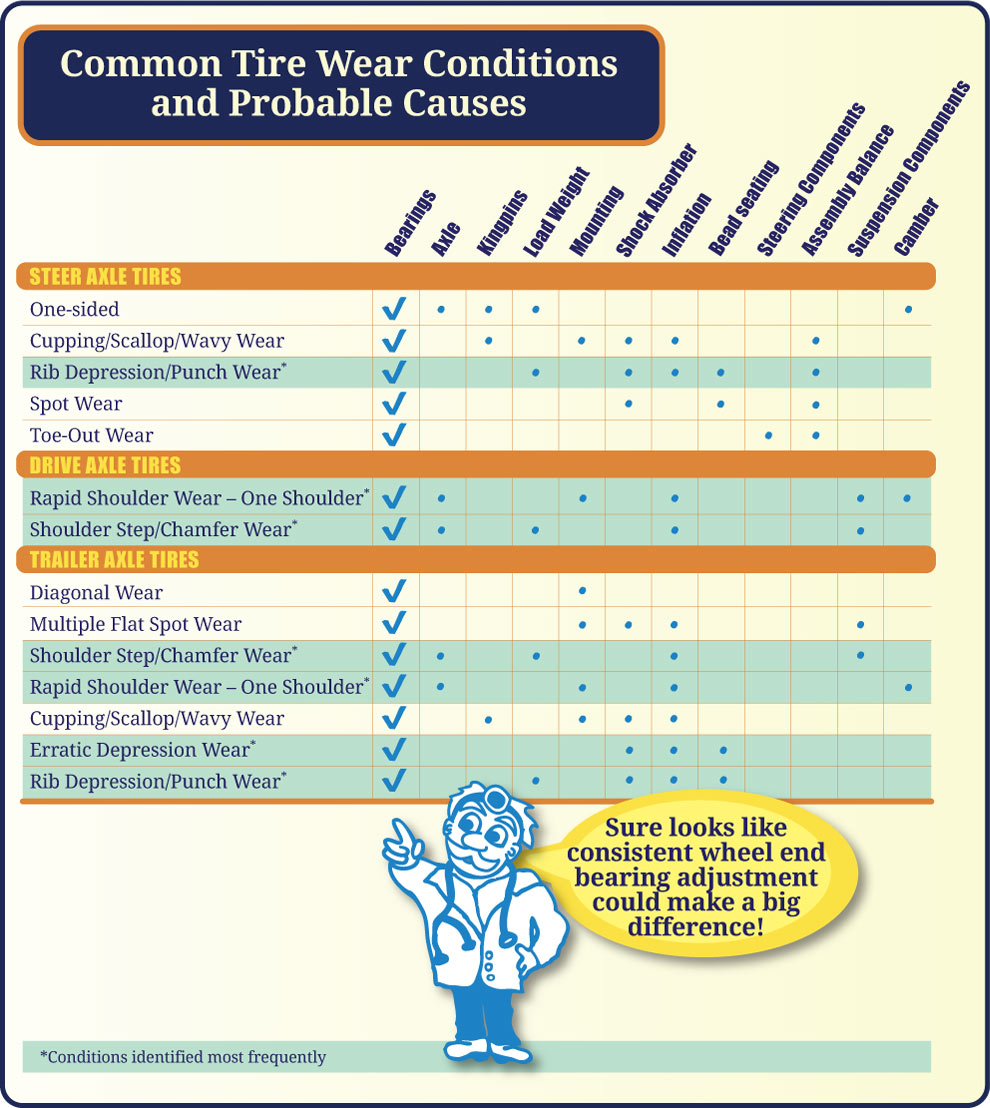

Referencing the Technology and Maintenance Council’s (TMC) Radial Tire Conditions Analysis Guide as a go-to resource for fleet managers, the author suggests the likely causes for shoulder wear, punch wear, and erratic wear are axle alignment and inflation. However, take a look at the TMC’s guide yourself and you’ll see there’s a major cause that was not addressed – improper bearing adjustment.

Referencing the Technology and Maintenance Council’s (TMC) Radial Tire Conditions Analysis Guide as a go-to resource for fleet managers, the author suggests the likely causes for shoulder wear, punch wear, and erratic wear are axle alignment and inflation. However, take a look at the TMC’s guide yourself and you’ll see there’s a major cause that was not addressed – improper bearing adjustment.

Go Back to the Source and Find the Truth – Improper Bearing Adjustment

Below is a chart we’ve made based on the TMC’s guide and the actual causes it discovered through exhaustive research and analysis. With one glance, it’s clear that improper bearing adjustment is an important cause that’s being ignored in many shops.

Improve Your Wheel End Bearing Adjustment Process

As our chart and the TMC’s Radial Tire Conditions Analysis Guide shows, improper/inconsistent bearing adjustment is a probable cause of irregular tire wear. Luckily, there is a way for technicians to quickly and accurately adjust wheel end bearings – Doctor Preload®. Used together with Temper-Loc® spindle nuts, our tools can eliminate inconsistent wheel bearing adjustments and potentially all of the tire wear issues presented above, delivering you substantial savings.

(Tire image credit: Heavy Duty Trucking)