Wheel End Adjustment Could be Costing You

Finally, there’s a way to make wheel end bearing adjustments accurate and consistent

TRUTH: most wheel end bearings are adjusted inconsistently

AND inconsistent bearing adjustments cause wheel end performance problems that cost you time and money.

Don’t blame the technicians

Don’t blame the technicians

No matter how many times vendors are brought in to do wheel end training, there will always be differences from wheel end to wheel end. The problem is the process, not the techs. Why? Because it’s impossible to make basic torque wrench procedures accurate and repeatable.

Blame the old process

Using a torque wrench, no one human can set two different wheel ends to the same exact bearing setting. And, it’s even harder for two different humans to adjust the same wheel end to the same bearing setting. Tiny, almost unrecognizable changes can result in serious wheel end performance issues, perhaps even a wheel end failure or wheel off.

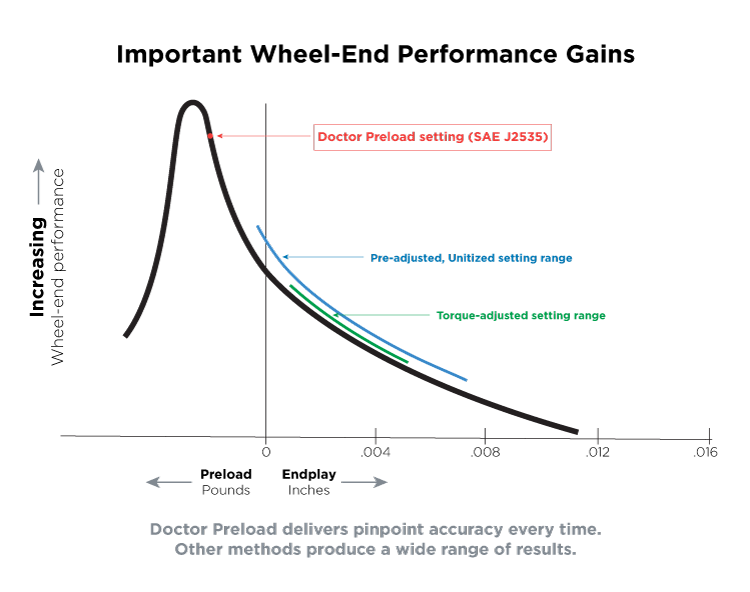

The curve in the illustration above demonstrates the range from preload to endplay/clearance. Along the curve, you’ll see the results of various bearing adjustment procedures. As you can see, different methods cover a wide area of the curve, meaning they result in significant variations.

And where there are variations, performance issues aren’t far behind; such as:

- Irregular tire wear

- Premature failure of wheel seals

- Persistent intermittent ABS fault codes

- Uneven wear of brake linings

- Dangerous wheel end failures

Torque wrench adjustment procedures, even when done with great care, still leave the door open for inconsistencies and variable bearing settings. A simple slip of the hands, distraction, or even something as small as a sneeze could result in several thousandths of an inch of endplay that may go unrecognized.

According to the Technology & Maintenance Council’s (TMC) standards for wheel bearing adjustment (outlined in Recommended Practice 618), the difference between too loose and too tight is between one thousandth and five thousandths of an inch. To put that into perspective, four thousandths of an inch is the width of just two human hairs. It’s almost imperceptible without measuring it.

TMC outlines a 9-step process to achieve the desired setting. Step #8, measuring, is the critical key. Unfortunately, far too few shops use a dial indicator to verify the correct measurement. They simply leave out that step in the process.

Measuring wheel end adjustments requires diligence. Consistently adjusting them, time after time, takes something more.

Arm your technicians with a better tool and a better process

Doctor Preload® bearing adjustment tools, used together with Temper-Loc® spindle nuts, eliminate inconsistent wheel bearing adjustments. In less than a minute, technicians can use the tool to adjust wheel end bearings to SAE standard light preload settings with measured, repeatable, accurate results. Doctor Preload guarantees that every technician is adjusting to the same setting across every wheel end.

And our customers corroborate our findings:

“When it comes to adjusting wheel ends, Doctor Preload allows every technician to get perfect preload setting, every time. No one can achieve the same level of consistency and accuracy using torque wrench procedures.” – Brock Ackerman, K&B Transportation

Over the past 10 years, fleets of all sizes have realized compelling benefits resulting in revolutionary wheel end performance levels. Doctor Preload ushers in a better way, finally giving technicians the tool they need to make consistent and accurate wheel end adjustments.